Views: 0 Author: Site Editor Publish Time: 2025-12-16 Origin: Site

Cement is a vital element in construction, from towering skyscrapers to cozy homes. However, not all cement is the same. The choice between hydraulic cement and non-hydraulic cement can affect the strength, durability, and cost of your project. In this article, you will learn about the key differences between these two types of cement. We will explore their properties, uses, and why choosing the right one matters for your project.

Prompt: The choice between hydraulic and non-hydraulic cement directly affects your project’s durability, cost, and environmental footprint. Understanding their differences is crucial for making the right decision.

Hydraulic cement is a fast-setting, water-resistant material that hardens by reacting with water. Its ability to set underwater makes it an essential component for various construction tasks, particularly in structures exposed to moisture.

Hydraulic cement, such as Portland cement, sets and hardens by chemical reactions with water. This process, known as hydration, allows it to maintain its strength even when submerged in water, making it highly versatile for wet or damp conditions.

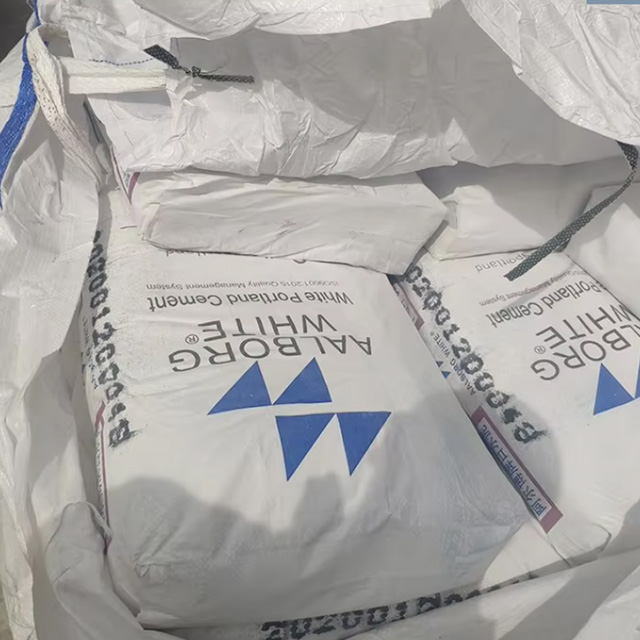

The most common type of hydraulic cement is Portland cement. However, there are other variants, such as aluminous cement, sulfate-resistant cement, and rapid-hardening cement, designed for specific purposes like high-heat resistance or quick setting times. Each type offers unique properties that cater to particular construction needs.

Hydraulic cement works through a chemical reaction between the cement and water. When mixed, the water combines with calcium silicates and aluminates in the cement to form hydrated compounds that harden over time. This process continues as long as water is present, giving hydraulic cement its water-resistant properties.

Unlike hydraulic cement, non-hydraulic cement does not set or harden in the presence of water. Instead, it relies on air for hardening, making it less suitable for wet conditions but ideal for dry environments.

Non-hydraulic cement, often made from lime or gypsum, requires dry conditions to set and harden. It does not react with water, and as such, is typically used for applications where moisture is not an issue.

The most common type of non-hydraulic cement is lime-based cement. Historically used in ancient buildings and still popular for restoration projects, lime is highly breathable, allowing moisture to escape from the building materials without trapping it inside.

Non-hydraulic cement hardens when exposed to air. As it absorbs carbon dioxide (CO2) from the atmosphere, it forms calcium carbonate, which gives it strength. This process, called carbonation, is slower compared to the immediate setting of hydraulic cement.

Prompt: Non-hydraulic cement, primarily lime-based, requires dry conditions for hardening and offers benefits like breathability for heritage restoration projects.

The primary difference between hydraulic and non-hydraulic cement lies in their reactions to water.

Hydraulic cement sets and hardens in the presence of water, while non-hydraulic cement requires air to harden. This makes hydraulic cement ideal for areas exposed to moisture, such as basements or underwater structures.

Hydraulic cement sets quickly, typically within a few hours, making it suitable for projects that require rapid completion. Non-hydraulic cement, on the other hand, hardens much more slowly, with curing times that may span weeks or even months.

Hydraulic cement is more durable and stronger, especially in wet conditions. It is ideal for foundations, basements, and outdoor projects that need to withstand water or harsh weather. Non-hydraulic cement is more fragile and susceptible to damage in damp environments.

Hydraulic cement is perfect for structures in contact with water, like dams, water tanks, and marine structures. Non-hydraulic cement is typically used for interior walls and masonry work in dry conditions, as well as for historical restorations due to its breathable qualities.

Hydraulic cement, particularly Portland cement, has a higher carbon footprint due to the energy-intensive production process. Non-hydraulic cement, such as lime, is more environmentally friendly and is considered a sustainable alternative for certain projects.

Feature | Hydraulic Cement | Non-Hydraulic Cement |

Water Reactivity | Reacts with water to set and harden | Does not react with water, hardens in air |

Setting Time | Quick setting, within hours | Slow setting, takes days to weeks |

Strength | High strength, durable in wet conditions | Lower strength, less durable in moisture |

Ideal Use Cases | Foundations, underwater structures, basements | Heritage restoration, interior walls in dry areas |

Environmental Impact | Higher carbon footprint (e.g., Portland cement) | More environmentally friendly, especially lime-based |

Durability in Wet Conditions | Excellent water resistance | Not recommended in wet conditions |

Prompt: Understanding the core differences between hydraulic and non-hydraulic cement helps you make the right choice for specific project needs, ensuring durability and cost-efficiency.

1. Fast Setting: Ideal for projects that require rapid construction or repair.

2. Waterproof: Perfect for areas exposed to moisture, preventing water damage.

3. High Strength: Provides long-lasting durability, especially in foundational work.

1. Limited Workability Time: Once mixed, it must be applied quickly, limiting flexibility.

2. Higher Cost: More expensive than non-hydraulic cement, especially when high-performance variants are needed.

3. Environmental Impact: The production of hydraulic cement contributes to greenhouse gas emissions.

Hydraulic cement is best used for projects requiring water resistance and structural integrity, such as foundations, basements, and underwater structures.

Feature | Advantages | Disadvantages |

Setting Speed | Quick setting for fast applications | Limited workability time |

Waterproofing | Ideal for moisture-prone environments | Higher production costs |

Strength and Durability | High strength, excellent for critical structures | Higher environmental impact (carbon footprint) |

Prompt: Hydraulic cement is perfect for demanding construction tasks, offering rapid setting and superior durability, but it comes at a higher cost and environmental price.

1. Cost-Effective: Non-hydraulic cement is often cheaper than hydraulic alternatives.

2. Breathable: Allows moisture to escape, preventing mold growth, making it ideal for historical restoration.

3. Environmental Friendliness: Non-hydraulic cement, especially lime-based, is more sustainable.

1. Low Strength: Non-hydraulic cement is weaker, making it unsuitable for high-load-bearing applications.

2. Vulnerable to Moisture: It cannot withstand wet conditions and will deteriorate in moist environments.

3. Slow Curing: The setting and hardening process is slow, requiring more time before use.

Ideal for restorations, masonry, and applications in dry climates, non-hydraulic cement is commonly used in heritage buildings and interior works where moisture is not a concern.

Choosing between hydraulic cement and non-hydraulic cement hinges on understanding your project’s needs. Whether it's water resistance, cost-effectiveness, or environmental impact, the right cement will ensure the success of your construction work.

● Hydraulic cement sets in water and is ideal for wet environments, while non-hydraulic cement sets in air and is better for dry applications.

● Hydraulic cement provides high strength and water resistance, but non-hydraulic cement offers sustainability and cost benefits in dry conditions.

Always seek expert advice to ensure that the cement selected aligns with your project’s requirements.

A deep understanding of these two types of cement will help you make a more informed decision that aligns with your construction goals, sustainability objectives, and budget constraints.

For expert advice and reliable cement solutions, trust SHISHAN.

A: Hydraulic cement is a type of cement that sets and hardens through a chemical reaction with water, making it ideal for construction in wet or underwater conditions.

A: Hydraulic cement hardens when mixed with water, while non-hydraulic cement requires air to harden. Hydraulic cement is ideal for wet environments, while non-hydraulic works best in dry conditions.

A: Use hydraulic cement for projects exposed to moisture, such as basements, foundations, and water tanks, as it provides water resistance and quick setting.

A: Hydraulic cement tends to be more expensive due to its advanced chemical composition and water-resistant properties, making it essential for moisture-prone projects.

A: Hydraulic cement offers quick setting, high strength, and superior water resistance, making it ideal for critical construction projects exposed to water.